by Alexander Muravsky, Head of the ‘MTLCD lab’

Since 2009, the laboratory of ‘Materials and Technologies of Liquid Crystal Devices’ in Minsk, Belarus, under my supervision, has grown from a small local lab into a modern research space, available to gifted students and to a significant community of liquid crystal scientists and researchers. Their work contributed to the fields of material science, chemistry and physics of liquid crystals alignment for LC photonics and LC display devices. Throughout its 15 years of academic study and the toughly gained know-how, knowledge and experience of industrial applied research were accumulated creating a rich soil for young brains providing unique local study opportunities for selected students from the Physical and the Chemical faculties of the Belarusian State University. Current researchers affiliated with the MTLCD lab can be found on all continents. They have collectively produced a number of well-cited scientific articles, sold patents, commercialized new materials and innovative equipment. The results of their collaboration include the creation of innovative production of polymerizable LC devices in Belarus.

Scientists say that ‘awareness of the problem is 80% of its solution’. It was fully confirmed in MTLCD lab collaboration with European Union. Thus joint efforts with Friedrich-Schiller University Jena, Germany on combination of the dielectric metasurfaces with high anchoring LC photoalignment material AtA-2 from MTLCD lab has led to the creation of breakthrough electrically tunable (ACS Photonics 2019, 6, 6, 1533–1540) and multi-responsive (ACS Photonics 2021, 8, 6, 1775–1783) dielectric metasurfaces. This work did not only give new answers, but pointed out to new challenges for photoalignment materials.

I realized that when you are working in the photonic lab or the ‘clean room’ and use new materials, safety issues require lots of time and effort and cannot be ignored. Standard photoalignment layers are obtained by wet coating of azo-dye thin films from 0.5% weight dimethylformamide (DMF) solution. It means that the DMF solvent represents 99,5% of the solution that is vaporized in the process and must be disposed of. Toxic vapors of efficient organic solvents inside the clean room with air recirculation systems decrease the lifetime of air filters. Moreover, the LED exposure or laser interference exposure should be processed in the photonic lab on the optical table. That means that the researcher needs to book the time slot, do the coating process inside the clean room and then return to the photonic lab for the exposure step. It should be taken into account that each entrance of the clean room costs time and budget for disposable clean clothes. There is an opportunity to improve the efficiency of the R&D lab work, if the wet coating of the photoalignment layer is obtained from aqueous/alcohol solution. Then it can be arranged right in the photonic lab using standard spin-coater or rod-coater equipment!

MTLCD lab took that big challenge and pioneered with the first water-coatable photoalignment materials. The synergy of: the MTLCD background experience in LC alignment materials (Front. Soft Matter 2024 4:1382925), the feedback from interaction with Liquid Crystal and Photonic Group from the Ghent University, Gent, Belgium and the valuable support of the EU4Belarus SALT/SALT II program – has brought to creation of a completely new type of high anchoring water soluble liquid crystal photoalignment materials AtA-2522 / AmA-2522 for geometrical phase LC photonic devices.

The continuous ‘toxic stress’ of the political crises of 2020s in Belarus has significantly ruined the possibility of further development of social networks from Minsk. Seeking for new formats of scientific collaboration in Europe I organized the ‘MTLCD lab. Community Building Event’ in the framework of the SALT project, “Programme EU4Belarus – Support to Advanced Learning and Training (SALT)”. The main goal was to bring together the community of liquid crystal scientists, who are experienced in photoalignment and involved in theoretical and experimental works on liquid crystal lenses, and who had former relationship to studying or working at Material and Technologies of LC Devices’ laboratory in Minsk, Belarus.

On February 21-23, 2025 the researchers, interconnected through affiliation to MTLCD lab, friends and members of the MTLCD lab have gathered at the École Paysanne de Lignerolles, Domaine de Lignerolles, Le Thieulin, France to share experience, discuss current problems, coordinate present activities and schedule joint research work plans. The host owner, Mrs. Anna Stepanoff, has made a remarkable walking tour round the picturesque landscape of the Lignerolles campus, including the Lignerolles castle with private forest, the artificial pool and the greenhouses.

Prof. Alexander Muravsky opened the meeting with a lecture on the contemporary level of understanding of liquid crystal alignment effect. He presented the state-of-art photoalignment materials for application in advanced geometrical phase liquid crystals devices. Ms. Veronika Stanevich, the junior researcher of the MTLCD lab from Minsk, gave a talk on her field of expertise on the azimuthal anchoring energy measurements and reviewed the experimental data of >10-4J/cm2 for contemporary high anchoring LC photoalignment materials, such as AtA-2 and AmA-2522 dyes. Ms. Fatemeh Abbasi, the PhD student from Ghent University, shared her feedback on successful obtainment of the photoalignment layer by spin-coating aqueous solution of experimental dye from MTLCD, France. Ms. Klaudziya Kamiak, the MPhil student from Friedrich-Schiller University Jena, talked about surface enhanced Raman Spectroscopy (SERS) for water contaminators detection. SERS samples’ optical quality requirement and possibilities of rod-coating technique for SERS substrates preparation were discussed.

The following speakers reported on present contemporary applications of the liquid crystals devices in Europe. Thus Dr. Veranika Biazruchanka, MTLCD alumni and former material engineer of a company from Belgium, observed the eyewear application of liquid crystal lenses and outlined the existing challenges and perspectives. Dr. Anatoli Murauski, the leading researcher of the MTLCD lab from Minsk, presented the developed electrically tunable liquid crystal prism for differential interference contrast (DIC) microscopy that was successfully applied to a polarizing microscope produced in Belarus. The potential of electrically switchable liquid crystal photonic devices application in Europe for healthcare and biological microscopy was outlined.

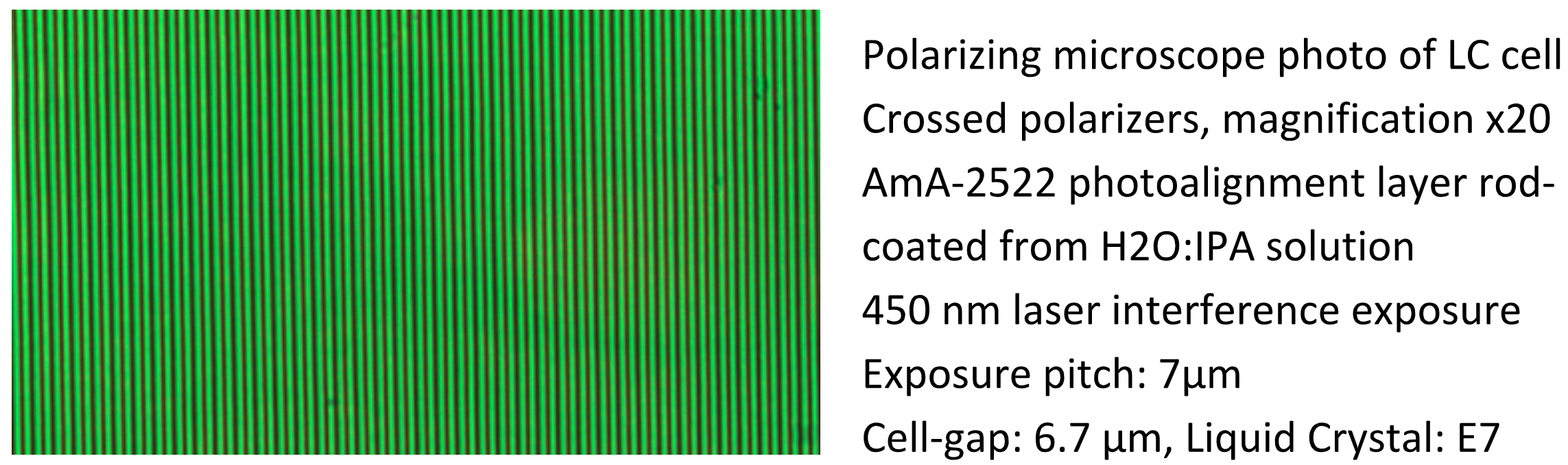

The experimental part for rod-coating of AmA-2522 from 0.5% solution in H2O:IPA (1:1) was a success. The rod-coater was installed directly in the meeting room, as the vapor of water and alcohol is completely harmless. The experienced senior users of MTLCD gave a master class on coating the thin films of new AmA-2522 dye with an eco-friendly solvent. The coating temperature of the substrate was 60°C, allowing the obtainment of AmA-2522 photoalignment layer with thickness 12±3 nm.

The substrates with rod-coated AmA-2522 photoalignment layer were assembled into cells and exposed to circular polarized laser interference exposure at the UGent photonic laboratory a few days later. The quality of the obtained LC grating by strong anchoring AmA-2522 photoalignment material is impressive.

The MTLCD lab community building event was a great success. It provided to liquid crystal scientists an opportunity to meet in person and to discuss plans and future community activities, as well as to promote and initiate the application in European Union of photoalignment materials and rod-coating technologies developed in Belarus for fabrication of innovative electrically switchable liquid crystal photonic devices: lens, prisms, gratings and other flat optical elements.

The support from the European Union initiative EU4Belarus SALT project, service contract No. 2025/4-3-105 is gratefully acknowledged.