- Comprehensive Safety Measures

Minimizes organic solvent vapor, ensuring a secure lab environment with a focus on both efficiency and safety.

- Temperature Control for Consistent Quality

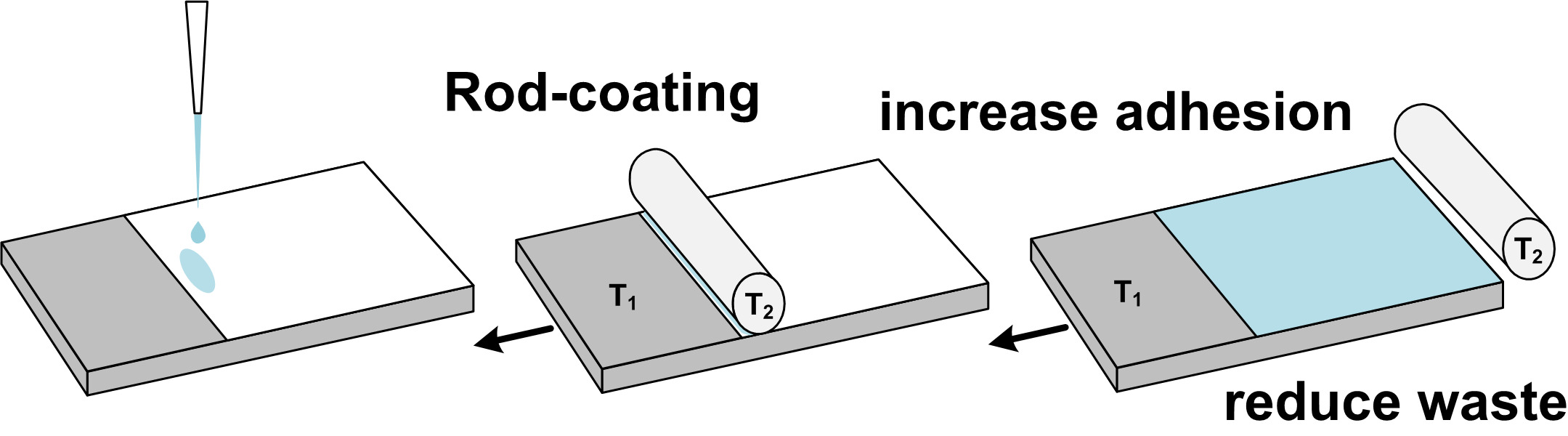

Independent control (RT to 120°C) of table and (RT to 60+°C) of rod ensures stable film quality, regardless of room temperature.

- Waste Reduction and Enhanced Throughput

Efficient material use minimizes waste and increases throughput for processing more film substrates.

- Versatile Coating

with Optimal Wetting

Precise temperature gradient control for various solvents, maintaining optimal wetting across the sample.

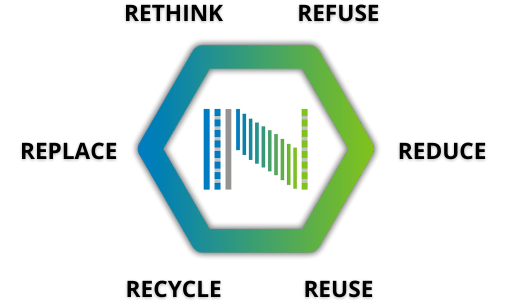

- Eco-friendly and

Safe Lab Practices

Aligned with the 'Green Lab' concept,

minimizes organic solvent vapor for a safer, sustainable lab.

- Efficient Material

Use for Cost Savings

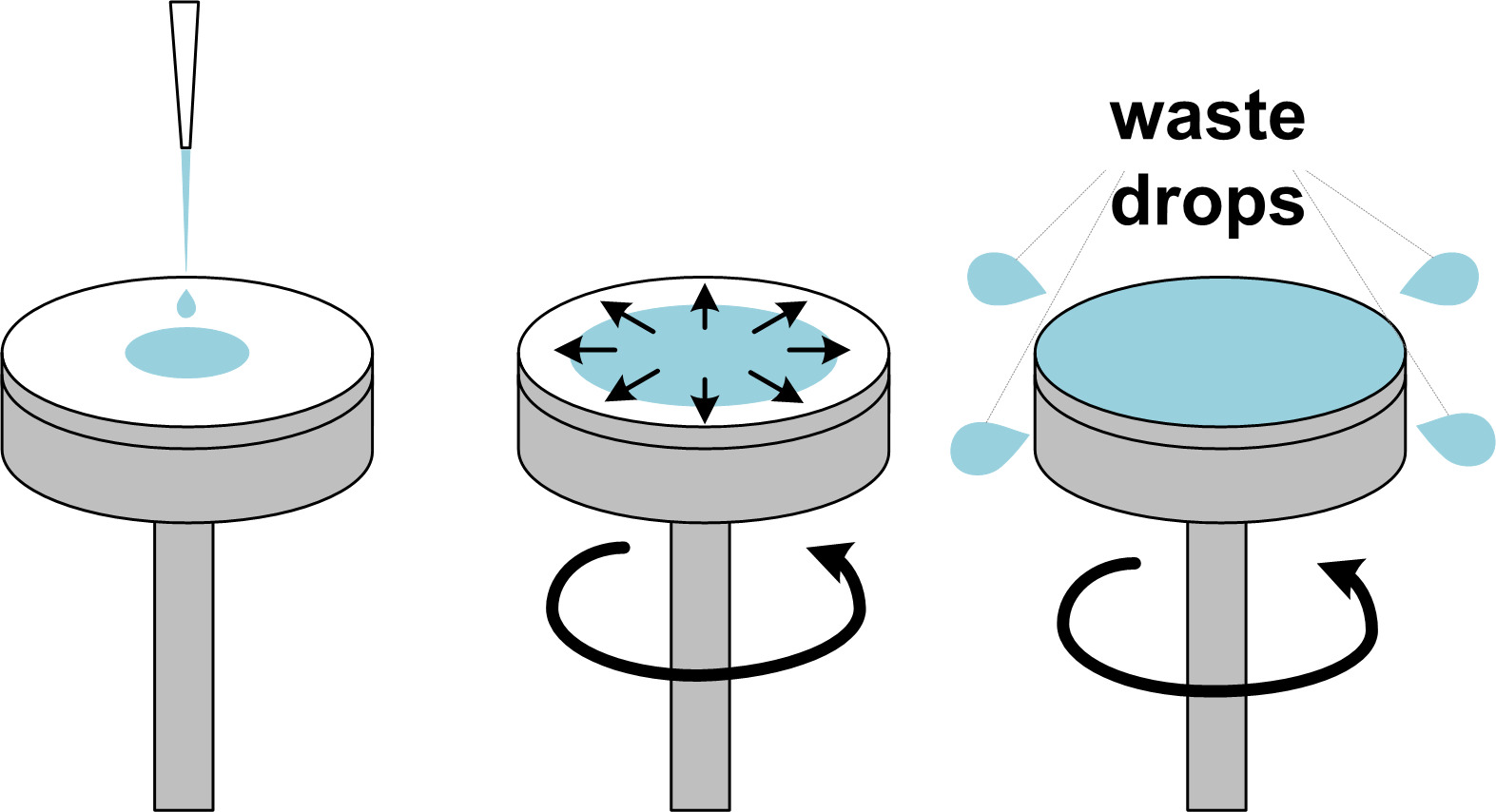

Rod-Coating uses 5-10 times less

material than spin-coating, reducing costs and allowing for smaller material volumes.

MY GREEN LAB

MY GREEN LAB